Product identification for fuel transportation

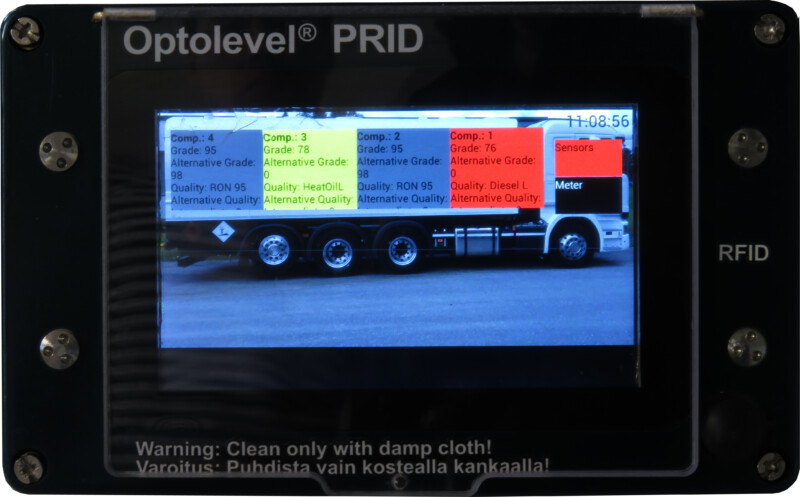

Product Identification Device

PRID is a Product Identification Device for fuel transportation in tank trucks and rail cars to prevent overfills, mixtures, and accidents in delivery and to protect the environment from pollution as well as to eliminate all human errors.

PRID Tag

The Optolevel® PRID Tag is the digital data storage of the Optolevel® PRID system. It holds the information about the installation location. No extra cabling is required because the Optolevel® PRID-unit uses the conducting product hose to communicate with the PRID Tag.

PRID OFP Tag

Optolevel® Overfill Prevention Tag is part of the full product identification and sealed parcel system. The OFP tag holds the information of which the user is able to know that the overfill prevention system is used and it is connected to the correct tank.

Product identification system

Product identification is a product mixing prevention system. The main purpose of the product mixing prevention is to avoid the mixture of products, e.g. different qualities of fuel during the loading of the compartment, or during unloading at the service station.

What is needed for a full PRID solution?

In order to have full product mixing prevention, it is required to install:

- A PRID-unit on the tank truck,

- A PRID tag on each loading arm in the terminal and in each well in the service station,

- A PRI OFP tag in each well in the service station.

How does product identification system work?

During the loading of fuel transport:

Each compartment of the truck gets the information of the loaded product quality during the loading process through the loading/unloading hose from the PRID tag or from loading plan. Each loading arm has a programmed PRID tag which has the information of the product quality loaded through it.

If the Information of the PRID tag from the loading arm matches the compartment information saved to the tank truck, the PRID-unit allows the loading by opening the bottom valve. Otherwise, the PRID-unit will not allow the bottom valve to open and thus prevents loading.

During the unloading of fuel transport:

The procedure is similar than in loading. However, instead of reading the PRID tag at the loading arm, it will read the PRID tag at the well in the service station. If the Information of the PRID tag from the un-loading arm matches the compartment information saved to the tank truck, the PRID-unit allows the un-loading by opening the bottom valve. Otherwise, the PRID-unit will not allow the bottom valve to open and thus prevents unloading.

Sealed compartment delivery in fuel transportation

Sealed Compartment Delivery means a process to seal any access to the tank compartments starting from the loading completion until the right unloading location.

What is needed to build a sealed compartment delivery for fuel transport?

Monitoring unit with GPS such as PRID-unit.

How does sealed compartment delivery work?

For every compartment, there is a given GPS location, where the unloading is allowed to happen. This location information is given to the monitoring unit during the loading of the compartment. The bottom valve of the compartment gets permission to be opened only at the given GPS location. This ensures that the product is delivered to the right place with the correct amount.

- Optolevel Oy

- Front Page

- About us

- References

- Contact