Optolevel® Product Identification Device

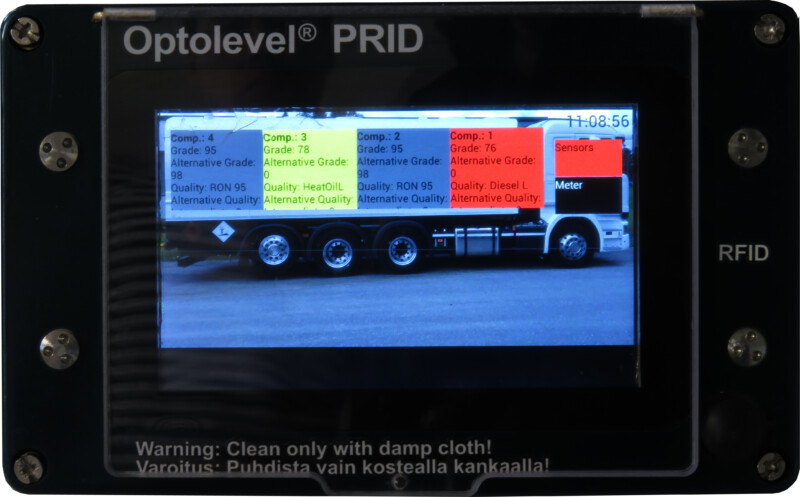

PRID is a Product Identification Device for fuel transportation in tank trucks and rail cars to prevent overfills, mixtures, and accidents in delivery and to protect the environment from pollution as well as to eliminate all human errors.

The PRID system consists of PRID-unit, PRID Tag, and OFP tag. To gain full potential of the system you need to have PRID tags installed on the service station tanks and on the loading arms in the terminal. By reading the information from these tags it is possible for this system to control the whole fuel transportation process, from the loading to the unloading, and to ensure that everything is going according to the plan.

Main Features of Product Identification Device

- Product Mixing Prevention in the tanks, compartments, and manifold.

- Level Monitoring: Multi-plug connection and 30 sensors/switch connections.

- Pump and free flow delivery meters:

- Slow start and stop control and slow flow control

- Clear user interface

- Interface to printer

- Sealed-Compartment-Delivery based on customer number, storage tank information or location.

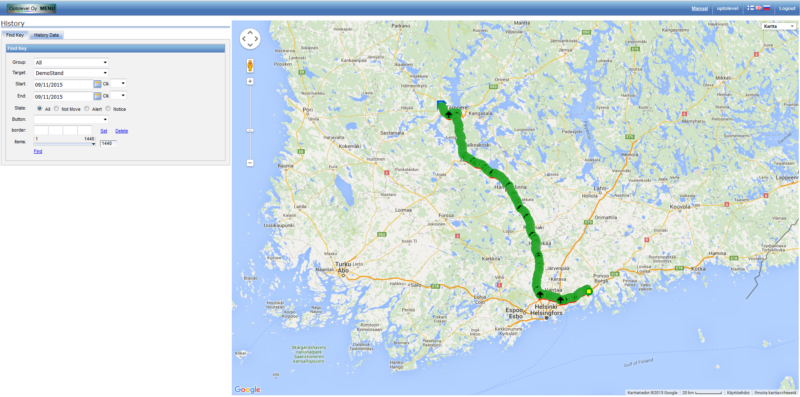

- Location Service:

- Tracking Service

- Alarms (in case of robbery)

- Status Update

- Additional services available subject to map service

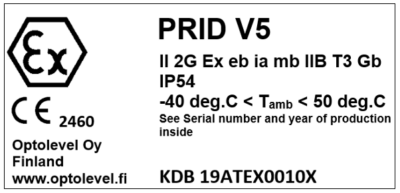

PRID Technical Specifications

- Twelve (12) connections for reading tags (EN14116):

- Up to 10 for reading tags via the API unloading/loading adapters

- Two (2) for reading tags via the vapour recovery hose or delivery swivel

- Three (3) delivery overfill amplifiers with overfill prevention tag reading and writing capabilities.

- 7” touchscreen.

- CAN-bus interface (for Optolevel® GateWay connection, loading schedule import, etc.).

- RS232-interface (configuration and updates).

- 2-16 GB internal memory for despatch list, loading schedule, configurations, blocked-list, event log and more.

Downloads

- Optolevel Oy

- Front Page

- About us

- References

- Contact